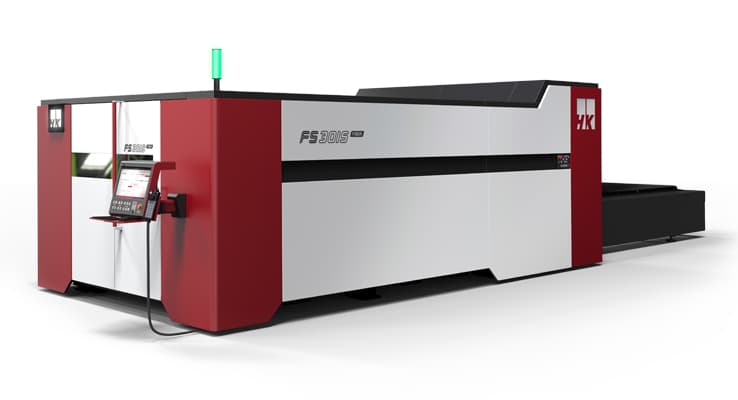

Precision Fabrication Machinery Works Inc

GSS Machinery has the expertise to handle all your product development needs, from concept conception to prototype, production and beta build.

Finishing machines are used to give the exterior of your metal production a beautiful finish. Deburring, rounding the edges, and other techniques are frequently used to accomplish this. Equipment calibration impacts production speed and finishing capability; hence, specific machines are more suited to a certain project than others.